BioFuel

What is BioFuel?

‘Biofuel’ is any fuel, liquid or gas, that derives from biomass or biomass residues. There are a number of fuels that are categorised as biofuels.

The most promising biofuels for use in the maritime industry are fatty acid methyl ester (FAME) and hydrotreated vegetable oil (HVO).

Currently, there are 3 different generations of biofuels, based on the source from which the fuel is delivered.

First generation biofuelsare produced directly from food crops, like corn, wheat, soybeans and sugar cane. But they are not characterised as sustainable fuels as they should be used primarily as edibles and the life-cycle assessment (LCA) of GHG emissions in first generation biofuels are generally assessed as being higher than those GHG emissions of fossil fuels!

Second generation biofuels are known as advanced biofuels and they are produced from nonedible crops or they have fulfilled their food purpose.

Third generation biofuels are delivered from algae and they are in a separate category as they are capable of much higher yields with lower resource inputs.

In this section

What are the available biofuels?

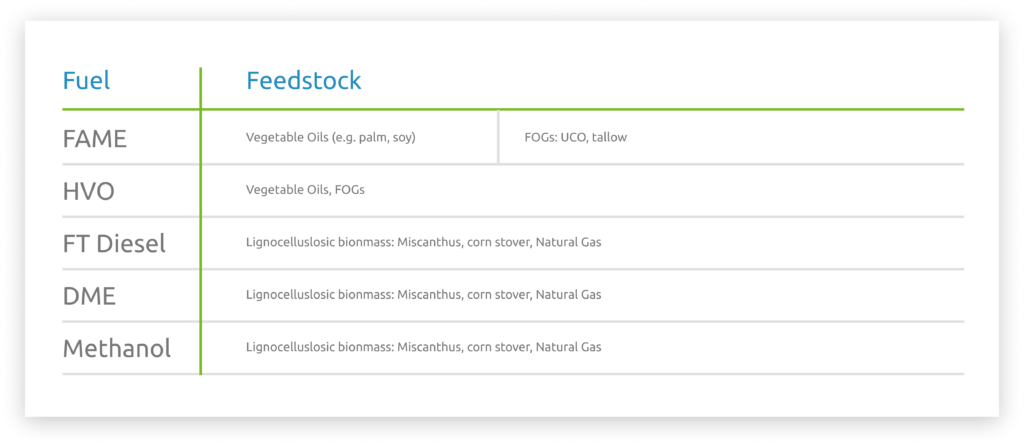

The feedstock from which a biofuel is produced is more important than conversion technology, in determining a fuel pathways’ GHG reductions.

FAME can be blended with conventional fuel in concentrations of up to 7% is permissible only as specified by ISO 8217:2017. The technical feasibility of various FAME biodiesel blends in shipping has been tested in a number of demonstration projects. FAME differs from MGO/MDO in terms of fuel stability. In general, FAME performs poorly in cold temperatures, is less stabile when blended, and has a short shelf life.

HVO is a high-quality fuel from which the oxygen has been removed using hydrogen, which result in long-term stability. The characteristics of HVO make it suitable as drop-in fuel substituting fossil fuels. In general, HVO is compatible with existing infrastructure and engine systems, subject to approval by the manufacturer. In some cases, modifications may be required (DNV GL, 2019). HVO stems from hydrotreatment.

FT diesel uses a less established technology, gasification with Fischer-Tropsch synthesis, but can use a wide variety of abundant feedstocks such as agricultural residues and even municipal solid waste. The FT synthesis process can produce a tailored range of hydrocarbons to meet the producers’ desired end-use, and this allows for greater engine compatibility. Renewable FT diesel is a biofuel that can be used without blending constraints, but this is an emerging technology and has high capital cost (ICCT, 2020).

DME and Methanol perform well in terms of possible feedstocks, industry interest, and evidence base to further growth. But these two fuels are less compatible with existing engines because both typically require dedicated or modified engines and/or fuel systems to store, distribute, and use the fuel. DME and Methanol are inexpensive and mature technologies.

How can the biofuels be blended?

Biofuels can be considered as a carbon reduction alternative to the shipping industry in a blended form with fuel or gas oil. Blending of biofuel with conventional bunkers is a very feasible option for shipowners, if the economics are optimal, as it gives freedom to manage just how much GHG reduction the owner want to achieve.

FAME biodiesel can be blended today with fuel and gas oil. However, issues with meeting the correct specifications when blending with MGO/MDO can arise above 20-30% FAME.

HVO can be used as a drop-in marine fuel blended with fuel and gas oil with no engine or system modifications (DNV GL, 2019). FT diesel can also be blended with fuel and gas oil and used as a drop-in marine fuel in diesel marine engines with no engine modification (ICCT, 2020). However, no sea trials have been executed with FT diesel. DME has been tested for use in a marine engine at up to a 40% blend with fuel and gas oil with system modifications to handle the low flash point, but it is expected to be used predominately in engines designed or retrofitted to run on only DME (ICCT, 2020).

How advanced is the infrastructure & watch out areas?

The general distribution network for the most dominant types of biofuels and feedstocks is well developed at the main ports around the world.

HVO can be distributed using the existing fuel and gas oil infrastructure. FAME, the use of existing bunkering infrastructure can prove more challenging, due to potential oxidation of FAME, therefore it is not to be stored for more than six months. FT diesel can be used as a drop-in marine fuel in diesel marine engines and using the current distribution network. DME can be blended in a small degree and used with current infrastructure with some modifications to handle the low flash point (ICCT, 2020).

Hence, for drop-in biofuels, it is possible to utilize the current bunkering infrastructure. However, dedicated biofuel bunkering operations are still not widespread in the global bunkering infrastructure outside the main hubs. The activity is primarily based around Rotterdam, where many shippers have tested or loaded biofuel and KPI OceanConnect has an office with experience in biofuels.

Are we commercially ready?

The current level of biofuel production is not able to replace the estimated 300m MT of conventional marine fuel used annually.

While FAME is notionally cheaper than HVO, it is known to be problematic in a wet environment.

Technically, HVO is a good option, however aviation market might command a much higher price, so without economic incentives, HVO will probably not have a dominant role in the maritime industry.

Therefore, biofuels are commercially ready, but it appears to be very attractive for other applications. However, this is where schemes such as the EU Emissions Trading System (ETS) could play a critical role in helping to find the most cost-effective home for the scarcer renewable fuels that have many potential deployments (Channoil, 2021).

What about pricing?

Biofuel price publications are provided by several large energy information providers, such as S&P Global Platts, Argus and Square Commodities.

In general, the prices of biofuels are 3 times higher than fossil fuels. So the solution of a blended product seems to be the most affordable way.

What is the environmental impact?

Environmental impact can be measured in several ways; therefore, it can often be difficult to make concrete suggestions to the environmental impact of a specific biofuel compared to a conventional marine fuel.

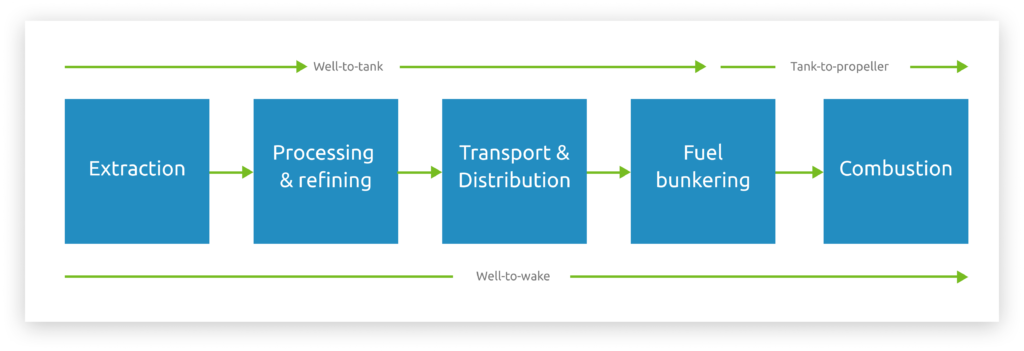

When looking at the emissions of a biofuel, it is important to understand the whole lifecycle analysis of the fuel. The actual GHG emissions from a given biofuel will depend strongly on the type of feedstock used and the fuel production process.

Biofuels are considered as a solution for GHG reduction although the use of these fuels does not directly reduce carbon emissions: CO2 from the combustion of biological materials adds CO2 to the atmosphere similar to combustion of fossil fuels. However, CO2 emitted from combustion of biofuels is considered as part of the natural CO2 cycle in which an equivalent amount of CO2 is captured from the atmosphere by the feedstock plants as they grow (DNV GL, 2019). Therefore, the different biofuels generally reduces the majority of the CO2 emissions (80-95%) compared to conventional marine fuels. However, the reduction in Nitric Oxide (NOx) and Particulate Matter (PM) emissions varies and is somewhat lower.

The International Sustainability and Carbon Certification

The International Sustainability and Carbon Certification (ISCC) system is establishing an international, practically viable, and transparent system for certifying biomass and bioenergy.

KPI OceanConnect is now certified with International Sustainability and Carbon Certifications – ISCC EU and ISCC Plus- for biofuel trading, reinforcing our commitment to responsible and sustainable energy practices.

ISCC EU and ISCC Plus are internationally recognized certifications that validate our organization’s compliance with stringent sustainability and traceability standards for biofuels. By attaining these certifications, we ensure that the biomass and bioenergy we utilize come from verified and responsible sources. By adhering to these standards, we are contributing to the preservation of ecosystems, biodiversity, and the well-being of local communities.

This milestone reinforces our position as a trusted and sustainable partner for our clients, stakeholders, and the communities we serve. We are proud to be associated with ISCC, which demonstrates our unwavering commitment to sustainability, environmental stewardship, and social responsibility.

Biofuel

What Is Biofuel?

Is this an established marine fuel today?

Is it a “Green Fuel”

What are the main safety considerations?

How is it stored?

How is it burned onboard?

Where can I get it from?

In this section

Speak to our experts

Our people think differently. We are an independent, privately owned, company with team members drawn from a wide variety of maritime backgrounds. We are passionate about finding new ways to help you run a cleaner and more efficient fleet, telling it straight and being transparent and inclusive.